Product and Service

SMF GROUP

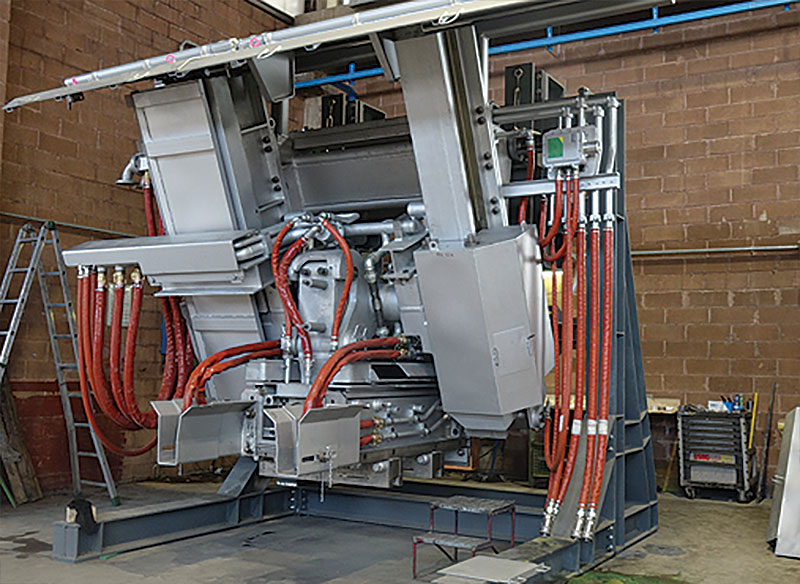

Melt Shop

Tundish wagons, ladle wagons, oscillating benches, continuous casters, false bars, draggers, straighteners, cooling plates, loading/unloading benches

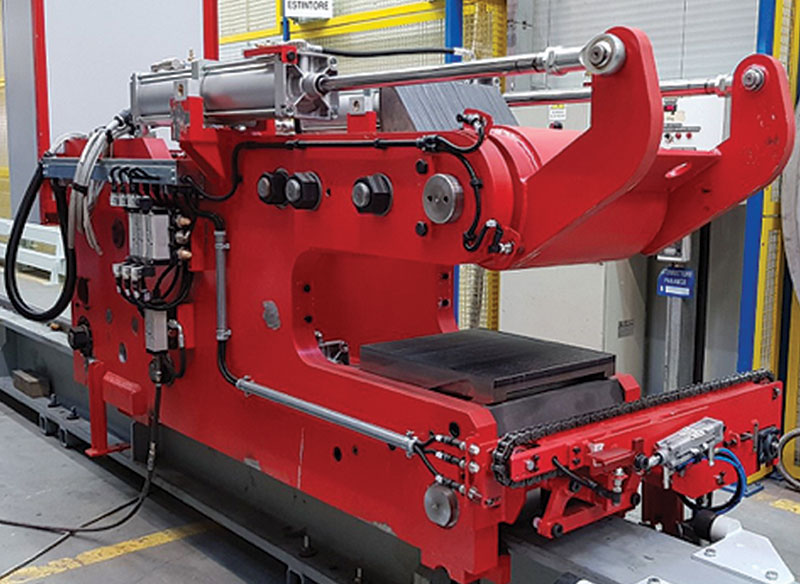

Rolling Mills

Stands, shears, pinch rolls, straighteners, roller tables, cooling beds, transfers, bar and coil finishing services

Furnaces

Loading/unloading machines close to reheating furnaces/forging furnaces and treatment furnaces in general

No-Ferrous

Automatic loaders for melting furnaces, single machines and turnkey plants for both upstream and downstream extrusion presses

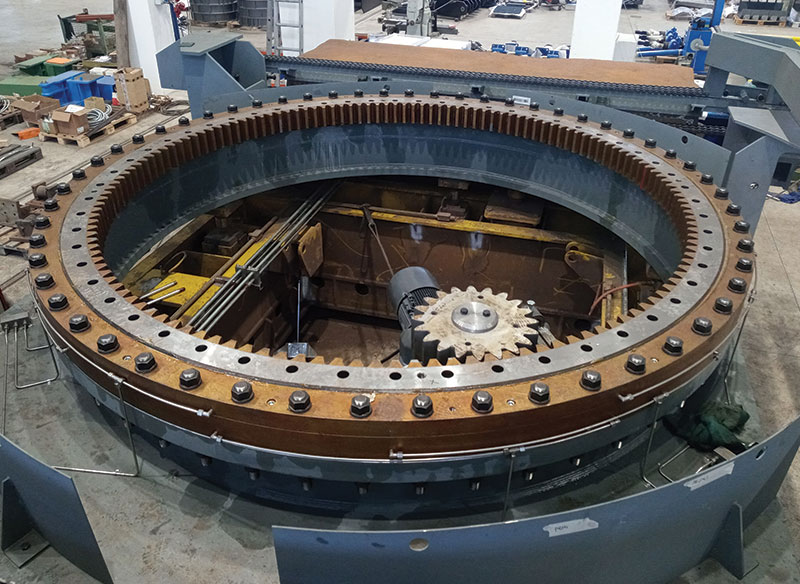

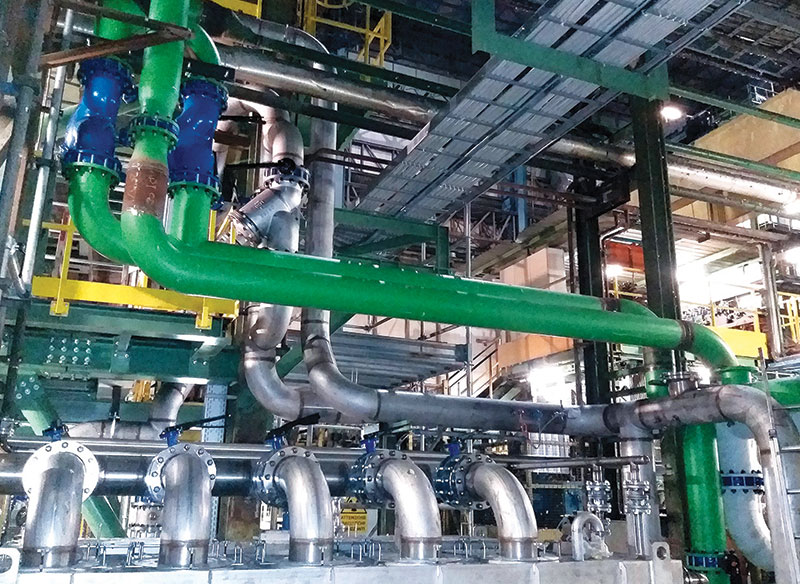

Plant / Equipment Upgrading

So-called revamping is a regenerative intervention on existing machinery and production lines to regain their functionality. This operation involves restructuring and refurbishing the machinery/plants by making technological, plant and structural changes as required to extend their life cycle and restore their full functionality as per the initial design.

Modern technology will replace obsolete technology, allowing the plant to increase its performance, reduce costs, save energy and increase safety.

On-site Service

Following the assembly and testing phase at our workshops, SMF provides the installation service at the end customer’s site with specialized personnel managed by the same supervisors who followed the on-site assembly. This will ensure the functionality and performance of the equipment supplied.

In addition to the installation activity, SMF also firmly believes in the maintenance aspect of the systems, starting with a systematic approach to the method, which is also linked to continuous on-the-job training.

SMF have own vehicles such as crane trucks and tractor-trailers that allow us maximum operational flexibility.